Home | Site

Map | Contact Information

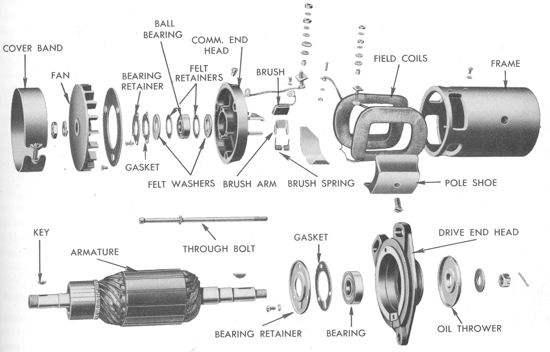

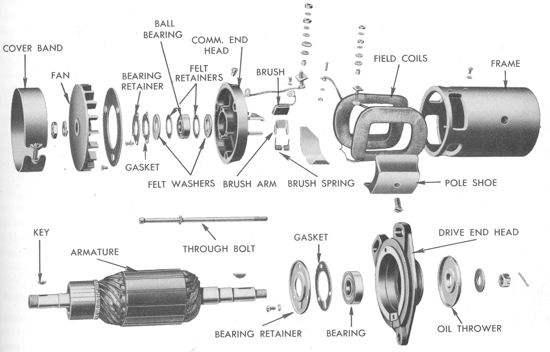

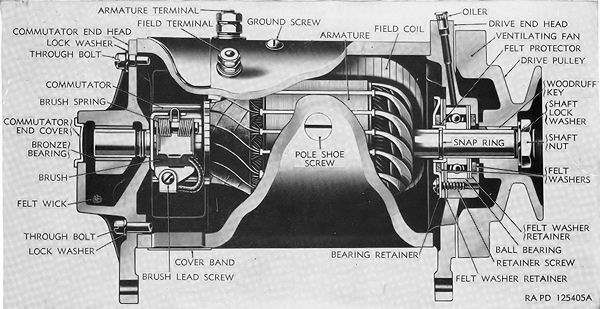

| An Auto-lite

generator will have a tag with the generator

number stamped on it, hopefully the tag is still in place. The

terminals are labeled in the illustration. The armature terminal (also

referred to as the generator terminal) is a larger

diameter than the field terminal since more current flows in that

circuit. The ground screw is simply threaded into the generator frame. The voltage regulator must be matched to the generator, see chart below for the proper regulator number. CJ-3As used Type A generators, other Willys Jeeps did use Type B. If the Type is unknown skip down to Determining the Generator Type. |

|

| First set the multi-meter to the

low ohms range. Connect one lead to the field terminal (small diameter)

and then measure the resistance to the armature terminal (large

diameter) with the other lead. See the photo to the right. A normal

reading is less than 10 ohms, here it is 3.7 ohms. |

|

| Now move the lead from the

Armature terminal to the Ground screw. Again the normal reading of less

than 10 ohms is seen in the photo. If the resistance of these two

checks is not less than 10 ohms each there is an internal problem with

the generator that must be repaired first. |

| To isolate the armature for this test remove the brush cover band. Lift one of the brushes and slip a cardboard strip between the brush and the commutator. It does not matter which brush is insulated since either will break the armature circuit continuity. In the photo the generator housing, or frame, has been removed for clarity. The cardboard strip can be inserted through the brush access holes without generator disassembly. |

| With the armature out of the

circuit repeat the first two tests. Check the resistance from the field

terminal to the armature terminal. For a Type A generator this

measurement will remain unchanged (less than 10 ohms) as seen in the

photo. This is because internally the field is connected to the

armature terminal. If this was a Type B generator the reading would be

an open

circuit, or no continuity. |

|

| Now move the test lead to the

ground screw. For a Type A generator this is now an open circuit, or no

continuity, as seen on the multi-meter. If this was a Type B generator

this reading would be less than 10 ohms because internally the field is

connected to ground. |

CJ-3A

Auto-lite

Generator Component Part numbers and

Specifications

| GDZ-48l7A | GDZ-600lD | GGW-4801D | |

| Armature | GDZ-2006F | GGY-2006F | GGW-2006F |

| Brush Set | GGU-2012S | GGY-2012S | GGY-2012BS |

| Commutator End Head Assembly |

GDZ-2087A | GGW-2002S | GGW-2002S |

| Commutator End Bearing | GBF-79 | GGU-38A | GGU-38A |

| Brush Arm (2 used) |

GCJ-26 | GCJ-26 | GCJ-26 |

| Brush Spring (2 used) | GBW-45 | GGY-45 | GGY-45 |

| Field Coil Assembly |

GDZ-1005 | GGW-1005 | GGW-1005 |

| Drive End Head Assy. | GDZ-1088A | GGW-1003 | GGW-1003 |

| Drive End Bearing |

X-295 | X-295 | X-295 |

| Pulley or Fan | SP-1885 | SP-1986 | SP-1986 |

| Voltage Regulator | VRP-6003A | VRP-6003A | VBE-6105A |

| Generator

Specifications |

|||

| Rated Volts |

6V | 6V | 6V |

| Rotation at the drive end |

Clockwise | Clockwise | Clockwise |

| Brush Spring Tension |

35-53oz. | 35-53oz. | 35-53oz. |

| Field Coil Draw |

5.0V, 1.3-1.5A | 5.0V, 1.3-1.5A | 5.0V, 1.4-1.5A |

| Motoring Draw |

5.0V, 3.9-4.4A | 5.0V, 3.9-4.4A | 5.0V, 4.1-4.6A |

| Output |

8.0V, 35.0A max, 2000 rpm max | 8.0V, 35.0A max, 2000 rpm max | 8.0V, 45.0A max,

2125 rpm max |

The CJ-3A Story | CJ-3A

Photos | CJ-3A Specs and Tech Tips | CJ-3A Literature | Siblings of the CJ-3A | Accessories | Links

3/07

www.cj3a.info © 2007