Home | Site

Map | Contact Information

Willys

Air Cleaners

How they work and upgrades

By Todd Gabrielson

In order to understand air cleaners, we have to understand dust.

That’s a big topic, so here’s an abbreviated course.

Dust size is measured in micrometers (usually shortened to microns),

and the actual shape and weight of the dust particle is dependent upon

on the type of dust it is. Chaff, road dust, snow, all have unique

characteristics that affect their behavior in the air stream and their

effect on engines and air cleaners. A micron is one millionth of a

meter. So for comparison, the diameter of a human hair varies from

about 40 microns to 120 microns. Copier paper is about 100 microns

thick. Humans lose the ability to see dust particles at about 40

microns. It’s important to filter the small dust particles even

if you can’t see them.

Dust has weight, mass, hardness and shape. Air cleaners, no matter what

type, exploit these characteristics to capture dust. In a diesel

engine, machine tolerances are much tighter than they are in a gas

engine; new gas engines are tighter than older units originally

supplied with the vintage Willys, which makes them more tolerant to

dust than a newer engine. Dust larger than 15-20 microns, depending on

its characteristics, is generally not so much of a problem either, as

it is typically too large to be airborne long enough to get to your

engine. Therefore, the dust that is most important to catch is the 3-15

micron dust, as this dust will stay airborne and can also damage your

engine.

Most heavy duty air cleaner systems consist of more than one

component; this is true of the Willys air cleaners as well. The picture

below is the Donaldson FAE07 air cleaner; this model was used on most

Willys Jeeps at one time or another. Oakes air cleaners were also

utilized, as was a Fram air cleaner that had a depth loading dry type

media, however, these were eventually replaced by Donaldson.

The critical parts of the air cleaner are described in this section:

The inlet section, the pre-cleaner section, the oil cup, mesh assembly

and outlet. Dust has weight, therefore when it is moving it has

inertia. The inlet section of the air cleaner does two things, sending

air in the direction we want it to go, and accelerating the air prior

to the pre-cleaner section. In this air cleaner the pre-cleaner creates

a tortuous path, a 180 degree turn that uses the inertia of the dust to

separate it from the air stream and drop it into the oil cup where it

is captured.

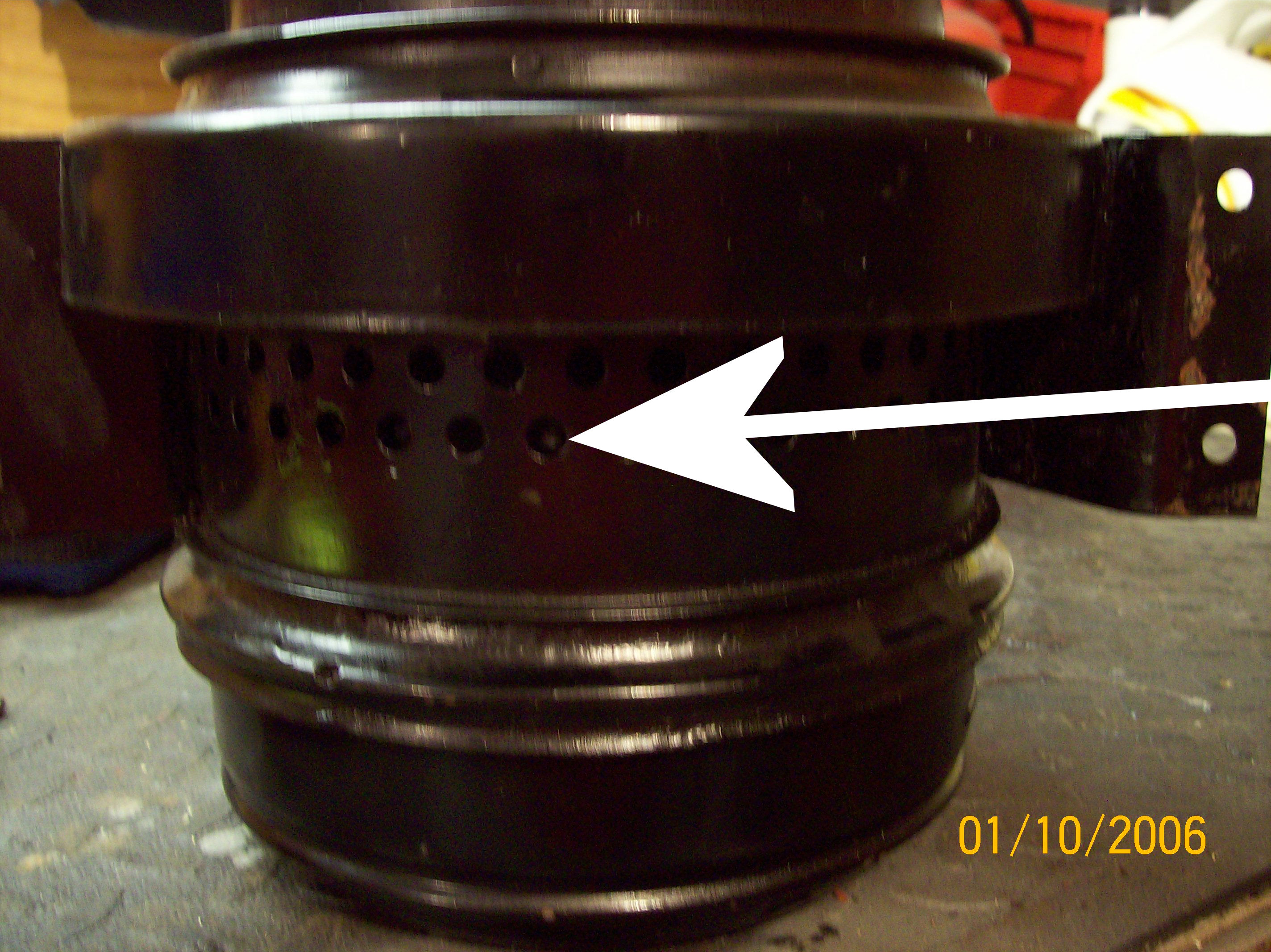

The above arrow shows the inlet section, which is designed to provide

the following functions:

- Add directionality to the air stream;

you’ll

notice on yours the inlet is only on one side of the air cleaner.

- Provide some level of pre-screening due to the

size

of the holes and accelerating the air stream in part to separate the

air from the heavier dust particles.

- The dome above the inlet section provides a

rain

shield function; water is quite heavy, so moving it that far from the

inlet results in a a minimal amount of water entering the air cleaner.

- The shroud on the inside of the pre cleaner

section

directs the dust laden air by turning it 90 degrees, down into the oil

cup, where it immediately turns 180 degrees to go up to the mesh

screen. This causes the heavier dust particles to separate from the air

stream and be captured by the oil.

The air stream is then directed up into the mesh assembly. This mesh is

coated with oil from the oil bath, the tortuous path (through the mesh)

is again used to separate the dust from the air stream and where the

dust is impinged on the oily mesh, the cleaned air then goes through

the outlet section to the engine inlet.

The mesh screen is an aluminized steel mesh captured in a steel frame,

in some oil bath units this screen is removable for cleaning, but in

the Willys Donaldson air cleaner it is not. Cleaning is

accomplished by following

the directions in a Donaldson

Service Bulletin.

Above is the outlet section, as you can see it has nice rounded corners

and smooth transitions from the air cleaner body, where the air was

slowed down (low velocity), to the outlet tube which has to match the

carburetor intake diameter. Smooth transitions reduce the overall

restriction in the air cleaner and allow for longer service life.

So here is an important tip: The air is now nice and clean and the most

important thing you can do from here on is make sure it stays that way.

The hose connections, rubber sleeve and boot at the carburetor need to

be in great condition in order to seal around the inlet/outlet tubing

and keep dust out. The level of vacuum pressure inside the ducting will

increase as the diameter decreases, at any given air flow, consequently

if you have a weak spot in the seals or clamps, a dust leak may occur

and it will go right into the engine.

In addition to making sure the seals and clamps are tight, it’s

important to service the air cleaner regularly. (See the link above for

the Donaldson service bulletin for these air cleaners) Most of

us, however, are restoring vehicles that have been ignored for some

time. It would be prudent to take the air cleaner off of the vehicle,

remove the oil cup and clean it completely, check for holes and leaks

as water often sits in these and will corrode them. JB weld is a good

way to repair the oil cup.

Service Suggestions

After removing the oil cup, submerge the rest of the air cleaner in a

bath of cleaning fluid, such as Stoddard Solvent or Kerosene. I would

use a low volatility bath, don’t use gas, please; I like you guys

too much. Let it rest for a while to loosen the built up grime and

junk. The mesh screen does not come out of these cleaners, so

don’t try - it will ruin the air cleaner.

Most of us are lucky to drive more than 1000 miles a year in our jeeps,

and unless these miles are all off-road, you shouldn’t need to

change the oil in the cup more than once per year. It’s pretty

easy to remove the cup, check the bath and then decide if you need to

change it or not. Check it a couple times a season; make a good

decision based on how you use your jeep.

These oil bath air cleaners are 98-99% efficient on dust larger than 5

microns, which is an acceptable level given the tolerances in a L134

engine. Newer tighter tolerance engines required higher levels of

efficiency, that’s why the dry type air cleaner was developed.

Upgrades

Some of us are looking for system upgrades to the oil bath air cleaner.

Donaldson makes a dry paper type air cleaner that is a great substitute

for the original, the FPG05. This is a very flexible air cleaner,

as it can be mounted horizontally or vertically, has the same outlet

diameter as the original so it will be a direct connection. The

FPG air cleaner is a two stage air cleaner with an inertial separator,

again taking advantage of the mass and velocity of the air stream, and

it also utilizes a high efficiency paper media as the final

stage. In addition to the air cleaner a host of accessories, such

as rain caps, ducting, and elbows are available to upgrade that fine

old Willys. Click here for the Donaldson webpage.

Credits to:

Donaldson Company Inc for technical information

Sarah Swenson

Randy Thompson

Tom Miller

Friends and associates

The CJ-3A Story | CJ-3A

Photos | CJ-3A Specs and Tech Tips | CJ-3A Literature | Siblings of the CJ-3A | Accessories | Links

10/11

www.CJ3A.info © 2011